Excavators are the quintessential and ubiquitous machinery in building, mining and construction industries. It simplifies heavy-duty operations and ensures smooth running without any hassles. However, so much for its simplicity, excavators are highly complex machines with thousands of smaller parts.

Thus, for an excavator operator or owner, understanding the functioning of each part is essential. A sophisticated excavator parts layout is a good way to learn how different parts are categorized and located on the machine. In this blog, we will explain different excavator parts and their respective categories.

Excavator Parts & Their Functions

1. Lower Structure

Track Chains

Track chains are a crucial component excavators. It consists of an interconnected metal links fastened together to create a continuous Track which provides required traction or machine movement at site. These links are typically made from high-strength steel and are designed to withstand the significant stresses and strains generated when these Excavators operate on uneven or rocky terrains.

Idler

An idler is a component of excavators used to support and guide the track chain. It is typically located at the front side of the machine and is responsible for maintaining the track tension, which helps to reduce wear & Tear and extends the lifespan of the track chain. The idler consists of a stationary wheel that rotates on a stationary axle, and it is designed to maintain a constant distance between the track chain and the ground.

Travel Motor

The travel motor is a critical component of an excavator that enables it to move from one location to another. It is a hydraulic motor mounted directly onto the final drive and utilizes Hydraulic system flow to drives the tracks and provides mobility to the machine. The travel motor receives hydraulic fluid from the machine's hydraulic system and converts the pressure into rotational force, which drives the tracks forward or backwards. The motor is designed to withstand the significant stresses and strains generated when the excavator operates on challenging terrain.

2. Upper Structure

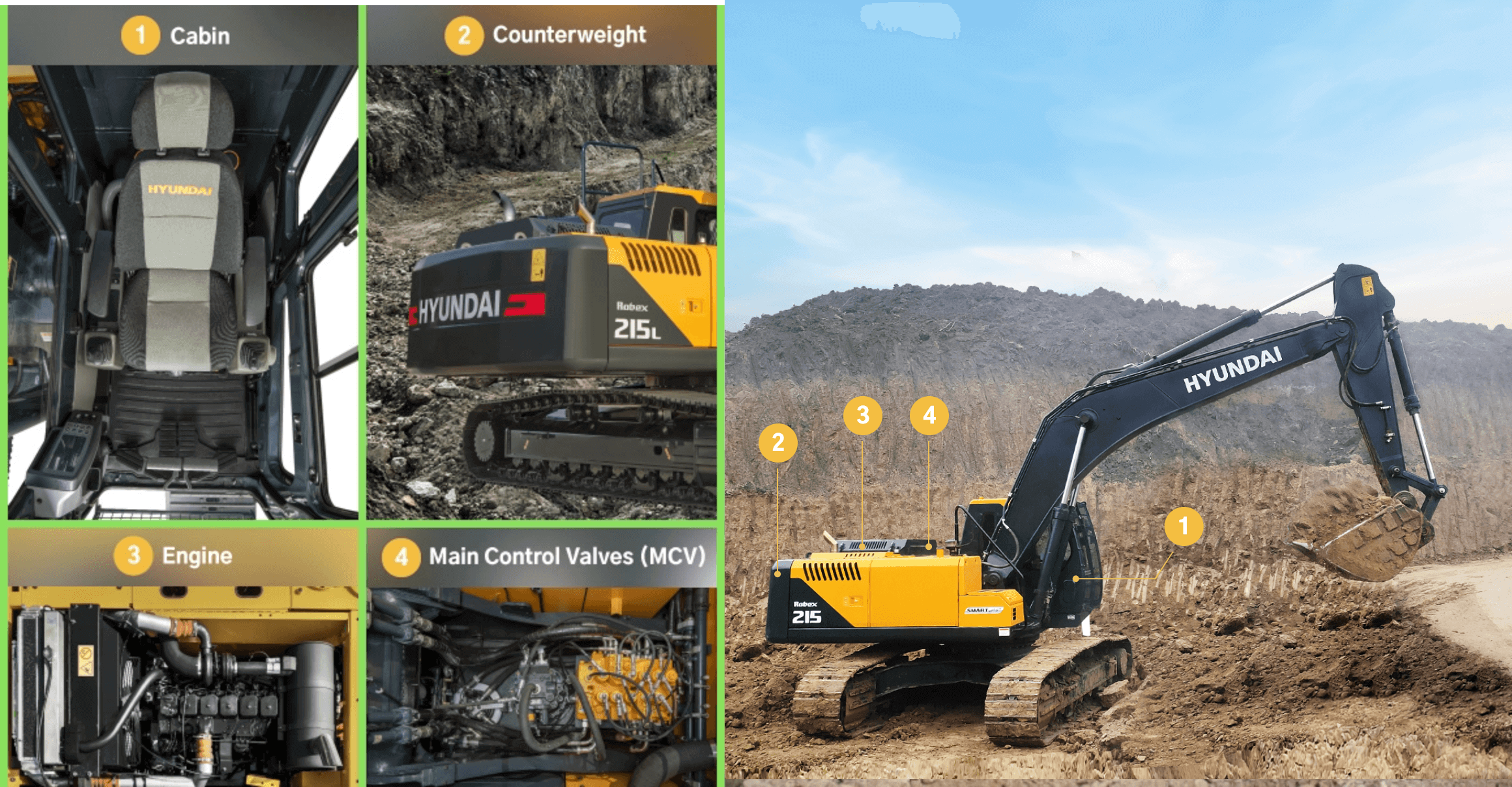

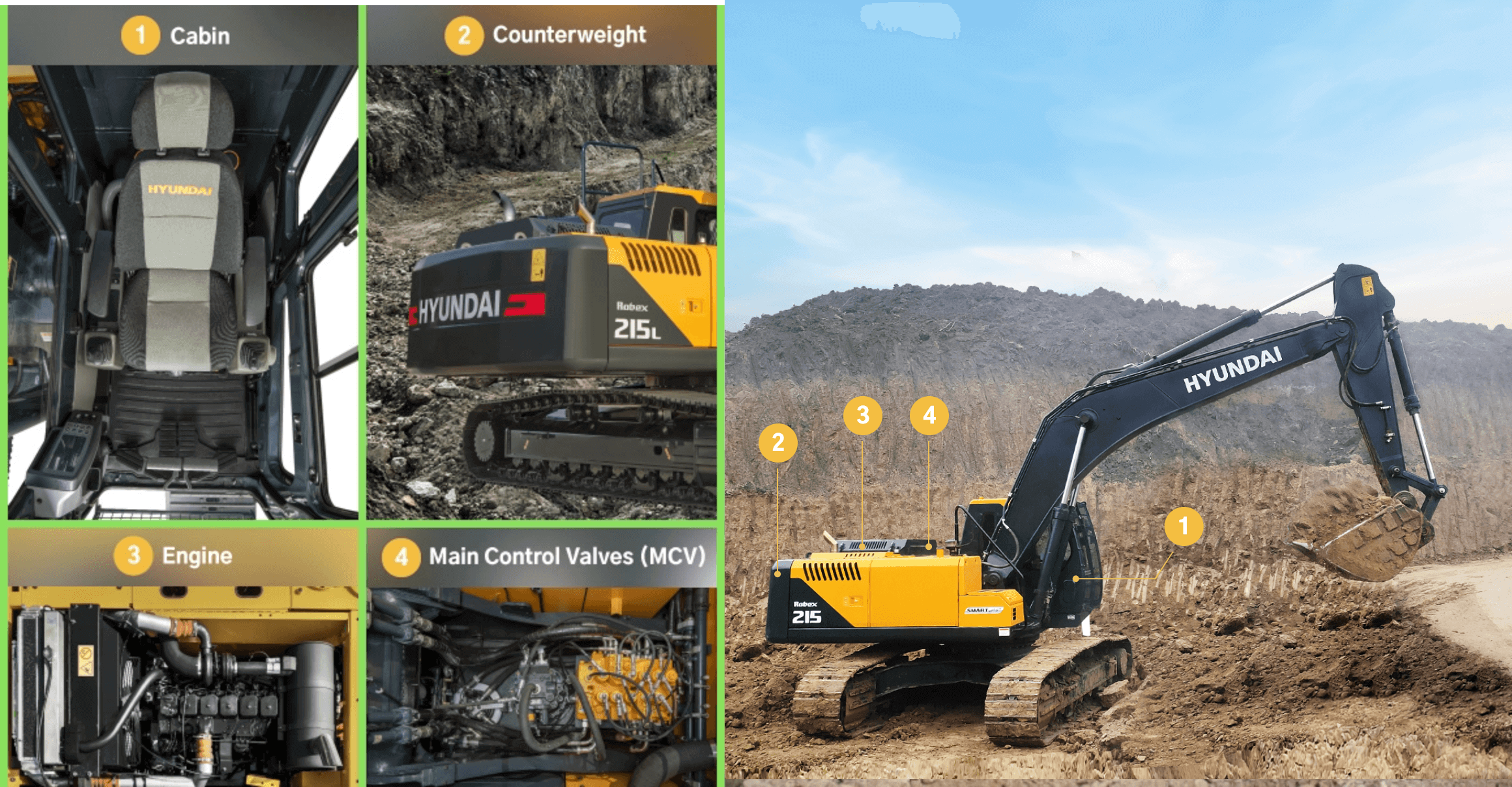

Cabin

The cabin in an excavator is the enclosed operator compartment where the operator sits to control and operate the machine. The cabin is typically designed to provide a comfortable and safe working environment for the operator, with features such as air conditioning, heating, vibrations and sound insulation to to significantly improve operator comforts & productivity. The cabin is also equipped with a variety of controls like the digital cluster, music system, charging support, AC, Safety Controls etc. to enable High Performance & Operating Convenience.

Counterweight

The counterweight in an excavator is a heavy metal component that is mounted at the rear of the machine to balance the weight of the machine & Provides Safe & Stable Working Environment while working. The counterweight is typically made from cast iron or steel and can weigh several tons, depending on the size and weight of the machine. The counterweight is designed to offset the weight of the excavator's boom, arm, and bucket when they are extended and in use, which helps to maintain the machine's stability and prevent it from tipping over.

Engine

The engine is the heart of an excavator, providing the power necessary to operate the machine's hydraulic system, tracks, and other components. The engine is typically located in the rear of the excavator, and it is often a diesel engine that is designed to provide high torque and power output with low fuel consumption. The engine is connected to the hydraulic system, which provides the force necessary to operate the machine's boom, arm, and bucket.

Main Control Valves (MCV)

The main control valve or MCV is a critical component of the hydraulic system in an excavator, controlling the flow and direction of hydraulic fluid to the various hydraulic Aggregates such as cylinders, motors & Valves that power the machine's movements. The main control valve is located near the hydraulic pump, which pressurizes the fluid before it enters the valve. The valve consists of multiple spools that direct the flow of hydraulic fluid to the various hydraulic circuits, allowing the operator to precisely control the machine's movements.

3. Front Attachment

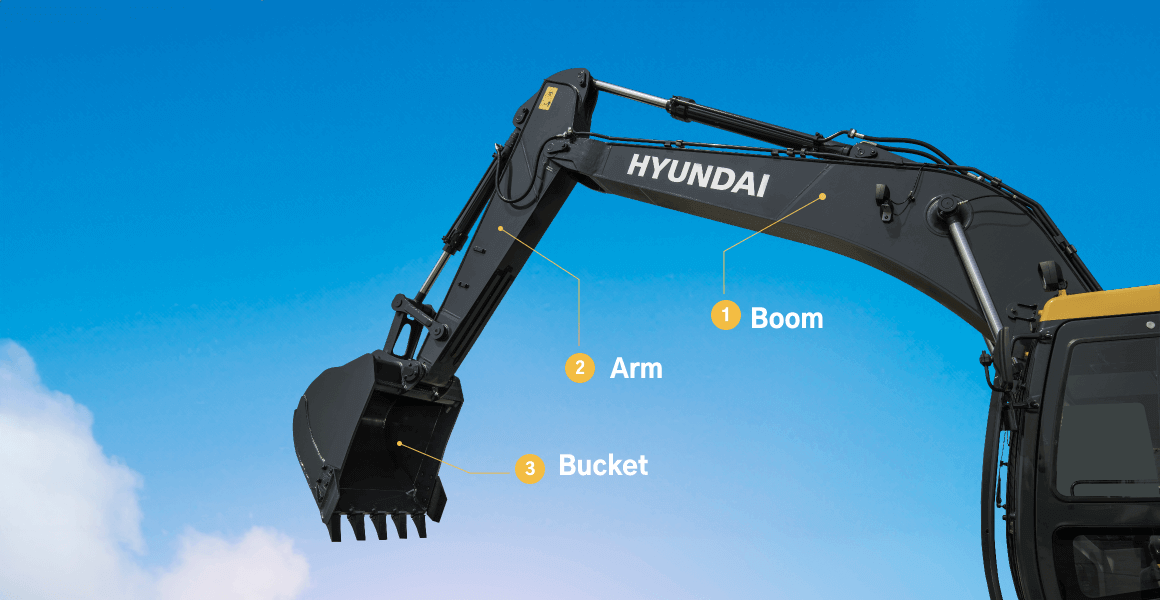

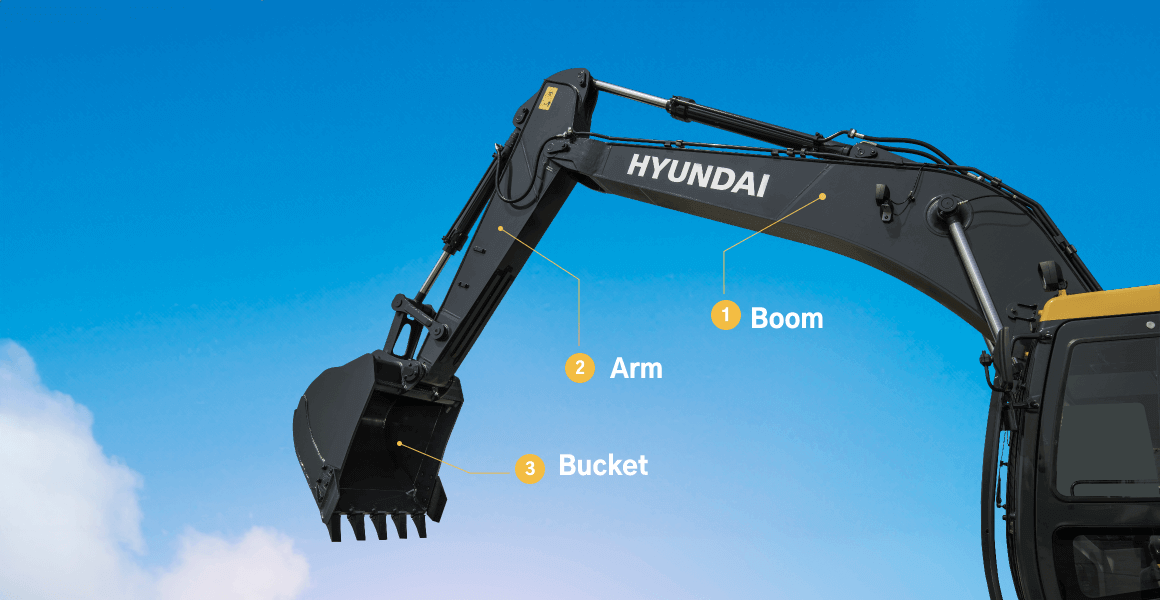

Boom

The boom is a critical component of an excavator, that extends outward from the machine's main body and is used to lift and move heavy objects. The boom is typically mounted on a pivot point at the machine's base and is operated by hydraulic cylinders that extend and retract to control the boom's movement.

Arm

The arm is another critical component of an excavator, consisting of a telescoping or fixed-length structure that extends from the boom and is used to control the machine's bucket or other attachments. The arm is typically operated by hydraulic cylinders that control its movement, allowing the operator to reach and move materials with precision. The length and shape of the arm can vary depending on the type of excavator and the intended use of the machine.

Bucket

The bucket is an essential attachment for an excavator, used for digging, scooping, loading and unloading materials such as soil, debris, or rocks. Buckets come in various shapes and sizes, depending on the type of excavation work and the materials being moved. The bucket is typically attached to the arm of the excavator and operated by hydraulic cylinders that control its movement, allowing the operator to dig and move materials with precision.

Final Thought

Apart from these major parts, there are other thousands of smaller parts involved. Understanding the functioning of these parts is extremely important for excavator owners and operators to carry out routine maintenance operations.

HD Hyundai Construction Equipment India , is manufacturing some of the Best & Finest excavators in India with high precision and robust quality. Our Its reliable hydraulic excavators are a combination of safety, comfort, efficiency, and durability, rendering complete control to the operator. Since 2007, HCE has gone above and beyond to meet your equipment requirements and make your business successful.

Abhishek Shukla

Assistant Manager

Abhishek is the assistant manager at Hyundai Construction Equipment India, with over 6+ years of experience in the excavator manufacturing industry. Abhishek is involved in making the digital marketing strategies, designing and managing product campaigns and is an expert in handling website design, development and SEO for Hyundai CE website.

![7 Types Of Heavy Earthmoving Equipment Updated [2024]](/assets/11-oct-2021-blog-detail-image-ca4a8e9c4503b51ab335d837740861d64a6be189d1c6ccd65386a11f1ca751cd.jpg)