Market: Infrastructure development in India has been the main demand driver for construction equipment (CE) over the years. The CE market is estimated to be close to 90,000 units per year in 2022.

Backhoe loader (BHL) market is estimated to be over 40% of total CE in India.

BHL units sold in India are estimated to be 40,000 units in 2019 during pre-Covid time, this is also the largest in the world. While in most of developed economies it is 2% - 10%

Backhoe Loader is an upgrade of tyre mounted Tractor with Digger attachment on rear and Loading attachment on Front side. BHL has stabilizers which are hydraulically operated and pushed on ground to lift tyres for earth work.

Since BHL is mounted on wheels it has the advantage of mobility which makes it ideal for movement for short distance travel for shifting from one site to another avoiding the need for hiring of transport vehicles.

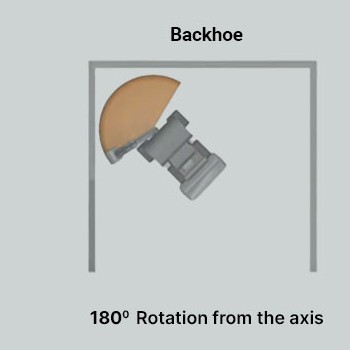

In Trenching operation – earth cutting for drainage, cable laying, piping laying the machinery need to travel – continuous shifting to cover considerable length of work. This is where considerable productive time is lost to reposition the machine in 7 steps as below:

Step 1: Retraction of stabilizers

Step 2: 180° turning of operator seat

Step 3: Lifting of loader bucket

Step 4: Repositioning of BHL

Step 5 to Step 7: Reverse Step3 to Step1

In slushy / muddy areas and during monsoon offers challenges to tyre mounted machines. The wet ground doesn’t offer good grip to tyres, this leads to higher risk in operation to both operator and machine and result in considerable productivity loss.

In hilly terrain, stone quarry sites, sand mining sites, we see similar productivity loss due to traction or tyre related Issues. This eventually leads to higher maintenance cost on components like PowerTrain and Tyres.

The product is suitable for utility jobs and short term contracting for low to medium level of productivity requirements and not an ideal solution as an all-terrain all season Solution.

Crawler Excavator is estimated to be ~25% of CE India market, growing year on year.

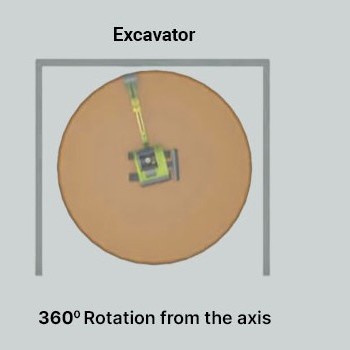

Crawler Excavators have relatively higher productivity compared to backhoe because of unique 360° swing (slew) angle feature, heavy chain mounted track design, higher stability, higher uptime due to lesser number of mechanical parts used for power transmission.

Apart from the above technical advantage, excavators also enjoy lower cost of operation because of less maintenance related components involved in Power trains

Compared to BHL, Excavator has lesser number of steps to perform to reposition in 3 steps only

Step 1: Dozer blade up

Step 2: Repositioning machine

Step 3: Dozer blade down

This 3 step operation makes Excavators a preferred choice among contractors for Trenching Jobs

Turning radius of Excavators (8 Ton) is estimated 2.5 meters vs. 8 meters for BHL, this makes Excavators more productive and suitable for work in confined (restricted) work areas.

Excavators have 360° Loading angle vs. 180° for BHL, this brings more flexibility to operators to use the machines comfortably to load trucks for longer hours.

8 Ton Excavators, like R85A SMART Plus are estimated to be 25% - 30% more productive than Backhoe Loaders. Also the product is available as all season, all terrain, operator friendly low maintenance machine.

Current trend: Smaller class of excavators in 8 Ton range is gradually replacing BHL in many applications. The most prominent applications where we see a trend are brick, kiln and urban infrastructure sites.

| Cost area |

Excavator |

Backhoe |

| Engine maintenance |

Required |

Required |

| Hydraulic maintenance |

Required |

Required |

| Tyre and brake maintenance |

X |

Required |

| Power Train - Transmission and Axle maintenance |

X |

Required |

| Road registration |

X |

Required |

| Yearly Road Tax |

X |

Required |

| Yearly Insurance Cost |

Low |

High |

Key Features and Advantage of R85A over Backhoe Loader

- Low Initial Investment & Better Return On Investment

- Low maintenance costs With Operator Friendliness

- Higher Productivity with similar Fuel consumption

Summary: If you are looking for an affordable solution to all your construction needs, please compare Hyundai's R85A Excavator with any Backhoe loader & decide the most suitable machine for your job.